mollwollfumble said:

What’s most surprising to me is that there’s not a whisper of a suggestion of alternative engine layouts that don’t have piston + crankshaft. Many such have been tried, including Wankel, gear, orbital, 5-cylinder skew plate. Are all the alternatives rubbish, or is it just that there’s so much experience with the conventional design that alternative layouts would be playing catch-up for a very long time?

There’s actually quite a lot of varying designs, but most of them are usually divided up into either “this is different just because I can” or “this is different and it’s crap but it’s my idea so I think it’s good”.

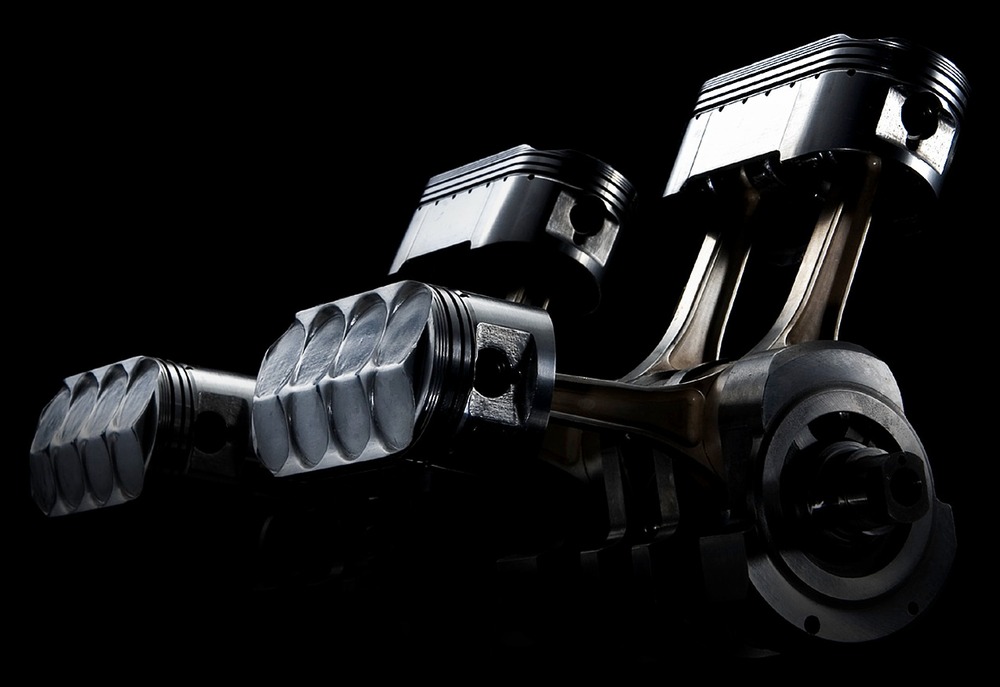

It basically boils down to the fact that it’s quite easy to seal a piston in a round tube with conventional rings, and do so for quite a long time. It’s not unreasonable to expect a modern engine to do at least 400,000 km+ before needing to be refreshed with a minor rebuild. For example there was a Toyota V8 ute in the US that was traded in for a new model, and Toyota took great interest in it, as it’d gone 1,600,000 km without the engine being refreshed. They put the engine on a dynometer and it made not a great deal less than the new version of that period.

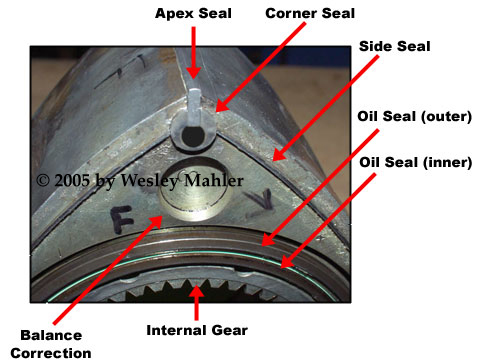

Engines that have to seal with varying radius curves or corners don’t do so well. It’s typically difficult to maintain a good gas seal in such engines. For example the Mazda rotary was perhaps the most successful engine of that type. Each rotor has a number of seals that have literally taken decades to get just right and be reliable. Just in time for the rotary to be placed in the history books as they aren’t very fuel efficient (too much internal surface area, so too much charge cooling effect and the chamber shape is terrible) and I think the emissions aren’t too good either. (might be wrong about that though).

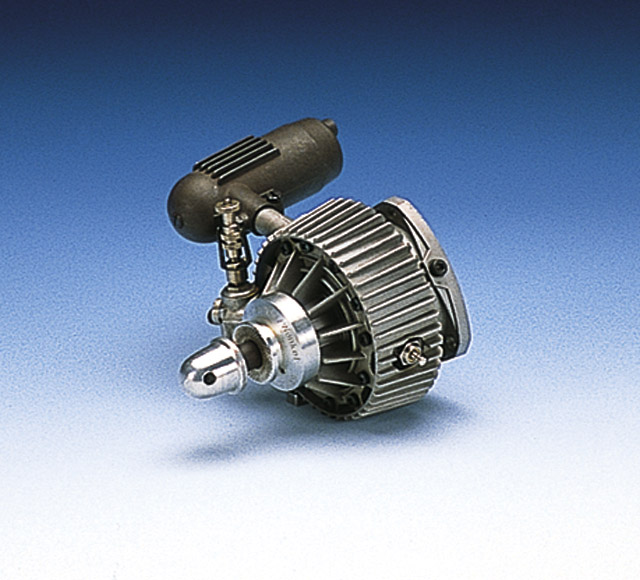

That being said, there are moves to use tiny rotaries as range extenders on hybrid cars. The reason being that if you can make an engine run under very specific conditions (rpm, load, etc) they can be quite efficient … even a rotary. And the rotary, being a very compact engine is a good match for such a job.

FWIW I have a model aircraft rotary engine, made by OS Max many years ago. I bought it from a bloke who bought it many years ago and it’s never been run. Looks like this ->

Honda was heavily involved in GP motorbike racing, starting in the 1960’s. In the 80’s the rules allowed for a two-stroke 500 cc engine and also a four stroke, but only with a maximum of four cylinders. To get enough power out of a four-stroke to match a two-stroke you really have to run the four-stroke very hard and to do that in that class with those rules you’d need to have a six or even an eight-cylinder engine, to get the required revs and also have enough valve area so as to pass enough air to make the power. But with a conventional four-pot it just wasn’t going to happen, But Honda was determined to try, so they came up with the NSR500; Four oval cylinders with each piston having two con-rods and recesses for the four inlet and four exhaust valves per cylinder.

It didn’t work, it was too difficult to get the oval(ish) rings to seal.

So we’re back to the conventional but ever-so reliable round cylinder. It works and works well.

Even with having to use a round cylinder, there’s still a lot of variations available for making the crankshaft do its job, and even a hell of a lot more for the cylinder head, to get the air in & out. Conventional poppet valves do work very well and they have been refined over a good century or so. I’m a fan of rotary-valve heads, as they allow for good breathing, a good combustion chamber shape, and since there’s no reciprocating parts you can rev them as high as you like. Bishop Engineering in Sydney came up with a very good design and it was to be used by Ilmor racing engines in Formula One. There’s an excellent article on them here. It also describes how the rules were changed to make them illegal even before they could be run in anger. They showed great promise and I have no doubts that they would have migrated to conventional road car engines. The sealing of the BRV was also tricky, but they seemed to get it under control after some development.

FWIW I’m also working with an Aussie mate that lives in China, on a rotary valve head. I made a hand-shake deal not not talk about it to anyone, but it’s delightfully simple and I reckon it would work extremely well. Hopefully one day I’ll be able to present some photos and data on it.

Australia has a good history of experimenting with rotary valve heads, one example is the Dunstan Head. There was also Harold Clisby, who made a successful one that was quite similar to the Dunstan head. Harold is more famous though for his very successful air-compressor company.

Anything more that you want to know, just ask.