Date: 3/03/2019 20:07:59

From: mollwollfumble

ID: 1354936

Subject: Bolt, nut, spanner, screw, screwdriver?

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Date: 3/03/2019 20:10:45

From: sibeen

ID: 1354938

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Archimedes’ screw has been around for a year or two. Perhaps someone looked at one of those and thought “what it?”.

Date: 3/03/2019 20:13:25

From: party_pants

ID: 1354939

Subject: re: Bolt, nut, spanner, screw, screwdriver?

interesting question.

seems they were used in printing and wine presses for hundreds of years before the idea was adapted into a metal fastener system.

Date: 3/03/2019 20:44:47

From: Michael V

ID: 1354947

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Date: 3/03/2019 20:50:34

From: Michael V

ID: 1354949

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Michael V said:

mollwollfumble said:

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Date: 3/03/2019 20:53:21

From: Peak Warming Man

ID: 1354950

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Michael V said:

Michael V said:

mollwollfumble said:

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Some good work there Michael.

Date: 3/03/2019 20:54:20

From: Michael V

ID: 1354951

Subject: re: Bolt, nut, spanner, screw, screwdriver?

https://en.wikipedia.org/wiki/Wrench#History

https://en.wikipedia.org/wiki/Screwdriver#History

Date: 3/03/2019 20:55:23

From: Michael V

ID: 1354952

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Peak Warming Man said:

Michael V said:

Michael V said:

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Some good work there Michael.

No worries.

;)

Date: 3/03/2019 20:58:53

From: Peak Warming Man

ID: 1354954

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Michael V said:

Peak Warming Man said:

Michael V said:

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Some good work there Michael.

No worries.

;)

Hehe

Date: 3/03/2019 22:37:58

From: Rule 303

ID: 1354971

Subject: re: Bolt, nut, spanner, screw, screwdriver?

It’s pretty easy to make a metal wood screw with a length of brass and a file. Trade teachers are renowned for setting such tasks to teach patience and perseverance, lateral thinking and adaptability.

Date: 3/03/2019 22:42:21

From: mollwollfumble

ID: 1354974

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Michael V said:

Michael V said:

mollwollfumble said:

Who invented the metal bolt, nut, spanner, screw, screwdriver, first standard screw thread?

Rivets were used before bolts. A screw thread in wood can be made by what is essentially whittling.

But I can’t see how it can be possible to make a metal screw thread without already having a metal screw thread. Unless …

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Not quite there yet. A screw cutting lathe needs a screw thread to drive the cutting tool that cuts the screw thread.

So where did the screw thread in the thread cutting lathe come from?

Date: 3/03/2019 22:43:28

From: captain_spalding

ID: 1354975

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

So where did the screw thread in the thread cutting lathe come from?

God made it.

Date: 3/03/2019 22:43:58

From: Rule 303

ID: 1354976

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Michael V said:

Michael V said:

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Not quite there yet. A screw cutting lathe needs a screw thread to drive the cutting tool that cuts the screw thread.

So where did the screw thread in the thread cutting lathe come from?

Do you know about Tap ‘n Die tools?

Date: 3/03/2019 22:47:06

From: party_pants

ID: 1354977

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Michael V said:

Michael V said:

Whitworth.

See:

https://en.wikipedia.org/wiki/British_Standard_Whitworth

https://en.wikipedia.org/wiki/Screw_thread#History_of_standardization

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Not quite there yet. A screw cutting lathe needs a screw thread to drive the cutting tool that cuts the screw thread.

So where did the screw thread in the thread cutting lathe come from?

They used to cut rifling in pistols by hand. Slow and expensive but it can be done.

Date: 4/03/2019 06:28:12

From: mollwollfumble

ID: 1355017

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Rule 303 said:

mollwollfumble said:

Michael V said:

Also:

https://en.wikipedia.org/wiki/Screw-cutting_lathe

Not quite there yet. A screw cutting lathe needs a screw thread to drive the cutting tool that cuts the screw thread.

So where did the screw thread in the thread cutting lathe come from?

Do you know about Tap ‘n Die tools?

Thanks, I was looking for a reference to that. Not by that name, but I had seen one. That’s the only way to cut an internal thread, but you need an external thread on the Tap ‘n Die tool to start with.

> They used to cut rifling in pistols by hand. Slow and expensive but it can be done.

Rifling doesn’t have to have accurate pitch. Any old variation in pitch will do.

> Wine and printing presses.

Good point. The threads there would initially have been made of wood? So we owe the origins of the bolt and nut to intoxicating liquor. It figures.

Look. I can see two possibilities. One is that some craftsman with a triangular file cut a spiral groove in some metal, such as brass, by hand. That’s still not good enough on its own unless someone sand-cast the first metal nut around the screw and finished the casting by hand using, for instance, a polishing compound between screw and nut.

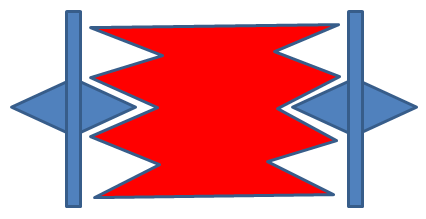

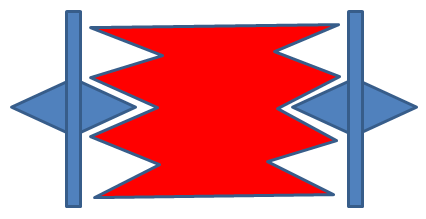

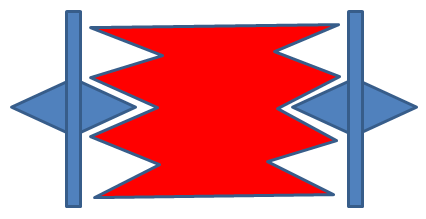

The other possibility is a tool that I’ve never seen but I think could be made. A hand-operated tool to make a double start thread could be made without the need for a screw thread to start it. Using a pair of wheel and axles set opposite one another mounted in a sand cast body. Each wheel is of a hardened material such as tool steel, rhombus in cross section with a pointed rim. Like this.

The wheels and axles could be made by hand or, easier and better, made in a lathe which was of rivetted construction.

By using axles that are not parallel to each other, the wheels could press double-start threads into a soft material such as brass or (possibly) annealed steel. The sand cast body would include handles, and look something like this, but containing the tool steel wheels.

Then sand-cast a nut around it, as before.

Once a double start thread was made, the use of gearing would allow it to be used on a thread-cutting lathe to make a single start thread, I think. Yes, it would. As well as making the thread cut depth more uniform, and changing the diameter, pitch and depth of the screw.

Michael V said:

https://en.wikipedia.org/wiki/Wrench#History

https://en.wikipedia.org/wiki/Screwdriver#History

Wrench before spanner. That makes sense. A screwdriver can be easily made from a metal rod by a blacksmith.

Date: 4/03/2019 08:22:18

From: mollwollfumble

ID: 1355026

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Rule 303 said:

mollwollfumble said:

Do you know about Tap ‘n Die tools?

Thanks, I was looking for a reference to that. Not by that name, but I had seen one. That’s the only way to cut an internal thread, but you need an external thread on the Tap ‘n Die tool to start with.

> They used to cut rifling in pistols by hand. Slow and expensive but it can be done.

Rifling doesn’t have to have accurate pitch. Any old variation in pitch will do.

> Wine and printing presses.

Good point. The threads there would initially have been made of wood? So we owe the origins of the bolt and nut to intoxicating liquor. It figures.

Look. I can see two possibilities. One is that some craftsman with a triangular file cut a spiral groove in some metal, such as brass, by hand. That’s still not good enough on its own unless someone sand-cast the first metal nut around the screw and finished the casting by hand using, for instance, a polishing compound between screw and nut.

The other possibility is a tool that I’ve never seen but I think could be made. A hand-operated tool to make a double start thread could be made without the need for a screw thread to start it. Using a pair of wheel and axles set opposite one another mounted in a sand cast body. Each wheel is of a hardened material such as tool steel, rhombus in cross section with a pointed rim. Like this.

The wheels and axles could be made by hand or, easier and better, made in a lathe which was of rivetted construction.

By using axles that are not parallel to each other, the wheels could press double-start threads into a soft material such as brass or (possibly) annealed steel. The sand cast body would include handles, and look something like this, but containing the tool steel wheels.

Then sand-cast a nut around it, as before.

Once a double start thread was made, the use of gearing would allow it to be used on a thread-cutting lathe to make a single start thread, I think. Yes, it would. As well as making the thread cut depth more uniform, and changing the diameter, pitch and depth of the screw.

Michael V said:

https://en.wikipedia.org/wiki/Wrench#History

https://en.wikipedia.org/wiki/Screwdriver#History

Wrench before spanner. That makes sense. A screwdriver can be easily made from a metal rod by a blacksmith.

There is a third possibility, but i don’t recommend it. Draw wire through a triangular dye to make triangular wire. Then glue the triangular wire around a rod to make a screw thread. The onlybreal advantage of this is that a nut could be made the same way. Not suitable for a fastening, but possible for a template screw for a thread-cutting lathe.

What about a thread-rolling flat dye? Simply cut by lathe without need for a screw thread?

This web link is interesting: The history of hardware tools describes the origins of the chain saw, circular saw and wrench.

It’s difficult to find on the web the origin of the spanner because Americans use the word “wrench” to refer to all three of wrench, spanner and shifting spanner. This image from 1834 is supposed to be the first spanner, but it is clearly an advanced form.

Date: 4/03/2019 08:34:05

From: ChrispenEvan

ID: 1355028

Subject: re: Bolt, nut, spanner, screw, screwdriver?

you could cut a thread using a rack and pinion to guide the cutting tool while the work rotated.

Date: 4/03/2019 08:35:19

From: ChrispenEvan

ID: 1355029

Subject: re: Bolt, nut, spanner, screw, screwdriver?

http://homepages.ihug.com.au/~dispater/turning.htm

Date: 4/03/2019 08:40:23

From: ChrispenEvan

ID: 1355030

Subject: re: Bolt, nut, spanner, screw, screwdriver?

https://www.gracesguide.co.uk/Henry_Maudslay:_Machine_Tools

Date: 4/03/2019 09:11:34

From: mollwollfumble

ID: 1355037

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

you could cut a thread using a rack and pinion to guide the cutting tool while the work rotated.

Thanks.

I was beginning to wonder about that. The rack would be moving at right angles to the shaft rotation. It would need to be parallel.

Using bevel gears to get the rack to move at the right speed relative to the shaft rotation speed? Hand cut gears? Or a universal joint? Or a 90 degree angle change using a belt drive?

Date: 4/03/2019 09:29:19

From: ChrispenEvan

ID: 1355043

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

ChrispenEvan said:

you could cut a thread using a rack and pinion to guide the cutting tool while the work rotated.

Thanks.

I was beginning to wonder about that. The rack would be moving at right angles to the shaft rotation. It would need to be parallel.

Using bevel gears to get the rack to move at the right speed relative to the shaft rotation speed? Hand cut gears? Or a universal joint? Or a 90 degree angle change using a belt drive?

machine tool fixed to rack. rack can slide. pinion driven by gears to give correct thread per inch count. pinion rotates, rack slides cutting thread while work is being spun.

Date: 4/03/2019 09:32:22

From: ChrispenEvan

ID: 1355049

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

mollwollfumble said:

ChrispenEvan said:

you could cut a thread using a rack and pinion to guide the cutting tool while the work rotated.

Thanks.

I was beginning to wonder about that. The rack would be moving at right angles to the shaft rotation. It would need to be parallel.

Using bevel gears to get the rack to move at the right speed relative to the shaft rotation speed? Hand cut gears? Or a universal joint? Or a 90 degree angle change using a belt drive?

machine tool fixed to rack. rack can slide. pinion driven by gears to give correct thread per inch count. pinion rotates, rack slides cutting thread while work is being spun.

you only need to accurately turn a short length of thread and from that you can then make longer and longer sections. first threads were hand cut though.

Date: 4/03/2019 09:37:06

From: Tamb

ID: 1355054

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

ChrispenEvan said:

mollwollfumble said:

Thanks.

I was beginning to wonder about that. The rack would be moving at right angles to the shaft rotation. It would need to be parallel.

Using bevel gears to get the rack to move at the right speed relative to the shaft rotation speed? Hand cut gears? Or a universal joint? Or a 90 degree angle change using a belt drive?

machine tool fixed to rack. rack can slide. pinion driven by gears to give correct thread per inch count. pinion rotates, rack slides cutting thread while work is being spun.

you only need to accurately turn a short length of thread and from that you can then make longer and longer sections. first threads were hand cut though.

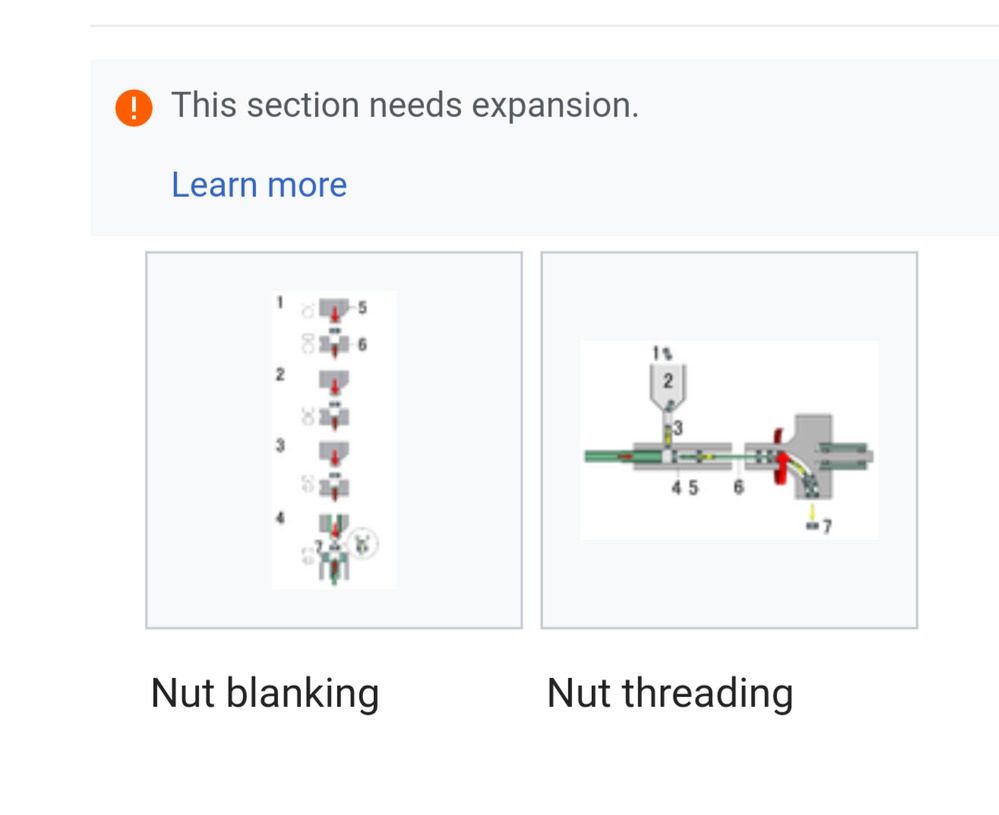

You can also make rolled threads:

Date: 4/03/2019 15:52:03

From: esselte

ID: 1355208

Subject: re: Bolt, nut, spanner, screw, screwdriver?

History of the Bolt

https://www.nord-lock.com/insights/knowledge/2017/the-history-of-the-bolt/

While the history of threads can be traced back to 400 BC, the most significant developments in the modern day bolt and screw processes were made during the last 150 years. Experts differ as to the origins of the humble nut and bolt. In his article “Nuts and Bolts”, Frederick E. Graves argues that a threaded bolt and a matching nut serving as a fastener only dates back to the 15th century. He bases this conclusion on the first printed record of screws appearing in a book in the early 15th century.

However, Graves also acknowledges that even though the threaded bolt dates back to the 15th century, the unthreaded bolt goes back to Roman times when it was used for “barring doors, as pivots for opening and closing doors and as wedge bolts: a bar or a rod with a slot in which a wedge was inserted so that the bolt could not be moved.” He also implies that the Romans developed the first screw, which was made out of bronze, or even silver. The threads were filed by hand or consisted of a wire wound around a rod and soldered on.

According to bolt expert Bill Eccles’ research, the history of the screw thread goes back much further. Archimedes (287 BC–212 BC) developed the screw principle and used it to construct devices to raise water. However, there are signs that the water screw may have originated in Egypt before the time of Archimedes. It was constructed from wood and was used to irrigate land and remove bilge water from ships. “But many consider that the screw thread was invented around 400 BC by Archytas of Tarentum, who has often been called the founder of mechanics and considered a contemporary of Plato,” Eccles writes on his website.

The history can be broken down into two parts: the threads themselves that date back to around 400 BC when they were used for items such as a spiral for lifting water, presses for grapes to make wine, and the fasteners themselves, which have been in use for around 400 years….

Date: 4/03/2019 17:30:17

From: Spiny Norman

ID: 1355256

Subject: re: Bolt, nut, spanner, screw, screwdriver?

There’s a couple of excellent books on this very subject.

I’ve read One Good Turn: A Natural History of the Screwdriver and the Screw and I’ve just ordered Exactly: How Precision Engineers Created the Modern World .

I was a bit apprehensive about the first one being interesting, but it ended up being one of my favourite reads. I’m very much looking forwards to the new book. Note that the links provided are to ABE Books, which have an excellent number of bookshops to draw from, to get all manner of books affordably.

Date: 4/03/2019 17:34:11

From: Ian

ID: 1355258

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Just when my head was threatening to drift away and abandon my neck altogether the forum starts into utterly facninating numbers and chinese passwords. Then I notice the Nuts and Bolts thread.. oooo, great stuff

(scratches head, if I can find it, and wonders) How do they manufacture nuts?

https://en.m.wikipedia.org/wiki/Nut_ Manufacture, gives only this..

Anyway, this is smashing viewing..

Bolt Manufacture

Date: 4/03/2019 18:13:23

From: Spiny Norman

ID: 1355276

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Sorry, I just this was amusing …

:)

Date: 4/03/2019 18:28:28

From: Ian

ID: 1355280

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Spiny Norman said:

Sorry, I just this was amusing …

:)

Screwy :)

—

Do you know about Tap ‘n Die tools?

I have a small set and a great big heavy duty one for threading pipes.. never use either of them.

Date: 4/03/2019 18:31:49

From: PermeateFree

ID: 1355281

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Ian said:

Spiny Norman said:

Sorry, I just this was amusing …

:)

Screwy :)

—

Do you know about Tap ‘n Die tools?

I have a small set and a great big heavy duty one for threading pipes.. never use either of them.

You could start a museum.

Date: 4/03/2019 18:35:03

From: Ian

ID: 1355286

Subject: re: Bolt, nut, spanner, screw, screwdriver?

PermeateFree said:

Ian said:

Spiny Norman said:

Sorry, I just this was amusing …

:)

Screwy :)

—

Do you know about Tap ‘n Die tools?

I have a small set and a great big heavy duty one for threading pipes.. never use either of them.

You could start a museum.

Or hold a sale.

Date: 4/03/2019 18:38:06

From: mollwollfumble

ID: 1355293

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Ian said:

Spiny Norman said:

Sorry, I just this was amusing …

:)

Screwy :)

—

Do you know about Tap ‘n Die tools?

I have a small set and a great big heavy duty one for threading pipes.. never use either of them.

That’s nuts.

Date: 4/03/2019 21:01:44

From: Spiny Norman

ID: 1355348

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Ian said:

—

Do you know about Tap ‘n Die tools?

Yep.

Date: 4/03/2019 21:03:21

From: roughbarked

ID: 1355349

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Spiny Norman said:

Ian said:

—

Do you know about Tap ‘n Die tools?

Yep.

Can tap a thread on a pin.

Date: 4/03/2019 21:43:31

From: mollwollfumble

ID: 1355369

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Ian said:

Anyway, this is smashing viewing..

Bolt Manufacture

Really enjoyed that, thanks. So the thread is rolled using a pair of flat plates.

Date: 4/03/2019 21:48:33

From: roughbarked

ID: 1355371

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Ian said:

Anyway, this is smashing viewing..

Bolt Manufacture

Really enjoyed that, thanks. So the thread is rolled using a pair of flat plates.

They aren’t really8 fflat. Some parts of them are at varying depths.

Date: 4/03/2019 22:05:44

From: Peak Warming Man

ID: 1355381

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Date: 4/03/2019 22:07:21

From: roughbarked

ID: 1355385

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Peak Warming Man said:

This is a good thread.

Both left and right can get along as long as you think before you tighten.

Date: 4/03/2019 22:07:32

From: ChrispenEvan

ID: 1355386

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Peak Warming Man said:

This is a good thread.

i nearly didn’t read it because, bolt, nut etc.

Date: 4/03/2019 22:08:26

From: roughbarked

ID: 1355392

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

Peak Warming Man said:

This is a good thread.

i nearly didn’t read it because, bolt, nut etc.

You just don’t do enough screwing.

Date: 4/03/2019 22:11:19

From: pommiejohn

ID: 1355395

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

Date: 4/03/2019 22:13:45

From: roughbarked

ID: 1355396

Subject: re: Bolt, nut, spanner, screw, screwdriver?

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

Seiko watch stems can be .05mm and they are very hard and brittle. It is difficult to get a good pair of end nippers that will cut it off at the precise point you desire rather than break at any lower point.

Date: 4/03/2019 22:15:53

From: roughbarked

ID: 1355398

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

Seiko watch stems can be .05mm and they are very hard and brittle. It is difficult to get a good pair of end nippers that will cut it off at the precise point you desire rather than break at any lower point.

The trick with cutting replacement stems was always to grasp it at the point reqired and pull the stem out to the hand set position, then do your snipping and a lot of the enerrgy is absorbed into pulling the stem back into the winding position.

Date: 4/03/2019 22:17:40

From: Michael V

ID: 1355400

Subject: re: Bolt, nut, spanner, screw, screwdriver?

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

Probably BSF or BSC.

Date: 4/03/2019 22:18:32

From: roughbarked

ID: 1355401

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

roughbarked said:

pommiejohn said:

It’s a fine thread indeed

Seiko watch stems can be .05mm and they are very hard and brittle. It is difficult to get a good pair of end nippers that will cut it off at the precise point you desire rather than break at any lower point.

The trick with cutting replacement stems was always to grasp it at the point reqired and pull the stem out to the hand set position, then do your snipping and a lot of the enerrgy is absorbed into pulling the stem back into the winding position.

After that, one has to file the sharp edges down so the crown doesn’t get cross threaded when screwing on. This is another time where the brittle nature of the stem itself will lend to snapping a catch to midwicket if you dont use soft hands.

Date: 4/03/2019 22:19:04

From: ChrispenEvan

ID: 1355402

Subject: re: Bolt, nut, spanner, screw, screwdriver?

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

it is the acme of threads.

Date: 4/03/2019 22:21:35

From: AwesomeO

ID: 1355403

Subject: re: Bolt, nut, spanner, screw, screwdriver?

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

Date: 4/03/2019 22:21:42

From: roughbarked

ID: 1355404

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

it is the acme of threads.

Dial screws on older Swiss watches are indeed very fine threads on very fine screws of quite long thread lengths. Can be very short and very tiny as well.

The thread on the stud screw which holds the balance to the cock, well that is an even finer thing of much greater beauty.

Date: 4/03/2019 22:21:45

From: ChrispenEvan

ID: 1355405

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

pommiejohn said:

Peak Warming Man said:

This is a good thread.

It’s a fine thread indeed

it is the acme of threads.

thought i’d just pitch that in.

Date: 4/03/2019 22:22:44

From: roughbarked

ID: 1355406

Subject: re: Bolt, nut, spanner, screw, screwdriver?

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

An Aboriginal historian told me that before white men actually arrived here, a steel axe could cost you two wives.

Date: 4/03/2019 22:23:25

From: roughbarked

ID: 1355407

Subject: re: Bolt, nut, spanner, screw, screwdriver?

ChrispenEvan said:

ChrispenEvan said:

pommiejohn said:

It’s a fine thread indeed

it is the acme of threads.

thought i’d just pitch that in.

It is a cant that is acceptable.

Date: 4/03/2019 22:24:21

From: party_pants

ID: 1355408

Subject: re: Bolt, nut, spanner, screw, screwdriver?

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

What’s the price for a Sudanese wife now?

Date: 4/03/2019 22:25:31

From: AwesomeO

ID: 1355409

Subject: re: Bolt, nut, spanner, screw, screwdriver?

party_pants said:

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

What’s the price for a Sudanese wife now?

A Japanese 4×4.

Date: 4/03/2019 22:25:51

From: roughbarked

ID: 1355410

Subject: re: Bolt, nut, spanner, screw, screwdriver?

party_pants said:

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

What’s the price for a Sudanese wife now?

A case of Cullinan diamonds

Date: 4/03/2019 22:25:54

From: ChrispenEvan

ID: 1355411

Subject: re: Bolt, nut, spanner, screw, screwdriver?

party_pants said:

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

What’s the price for a Sudanese wife now?

tree fiddy.

Date: 4/03/2019 22:26:26

From: roughbarked

ID: 1355412

Subject: re: Bolt, nut, spanner, screw, screwdriver?

AwesomeO said:

party_pants said:

AwesomeO said:

The other day on railways Michael Portillo went to a needle factory, again mass production using wires and presses. He said back in the day a packet of English needles would buy you a wife in the Sudan.

What’s the price for a Sudanese wife now?

A Japanese 4×4.

Preferably with a mounted .50 cal.

Date: 4/03/2019 22:30:28

From: roughbarked

ID: 1355413

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

ChrispenEvan said:

pommiejohn said:

It’s a fine thread indeed

it is the acme of threads.

Dial screws on older Swiss watches are indeed very fine threads on very fine screws of quite long thread lengths. Can be very short and very tiny as well.

The thread on the stud screw which holds the balance to the cock, well that is an even finer thing of much greater beauty.

http://www.ofrei.com/page1014.html

Date: 4/03/2019 22:35:30

From: party_pants

ID: 1355418

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

AwesomeO said:

party_pants said:

What’s the price for a Sudanese wife now?

A Japanese 4×4.

Preferably with a mounted .50 cal.

I’m all out of them.

Date: 5/03/2019 04:55:32

From: mollwollfumble

ID: 1355483

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

Look. I can see two possibilities. One is that some craftsman with a triangular file cut a spiral groove in some metal, such as brass, by hand. That’s still not good enough on its own unless someone sand-cast the first metal nut around the screw and finished the casting by hand using, for instance, a polishing compound between screw and nut.

The other possibility is a tool that I’ve never seen but I think could be made. A hand-operated tool to make a double start thread could be made without the need for a screw thread to start it. Using a pair of wheel and axles set opposite one another mounted in a sand cast body. Each wheel is of a hardened material such as tool steel, rhombus in cross section with a pointed rim. Like this.

The wheels and axles could be made by hand or, easier and better, made in a lathe which was of rivetted construction.

By using axles that are not parallel to each other, the wheels could press double-start threads into a soft material such as brass or (possibly) annealed steel. The sand cast body would include handles, and look something like this, but containing the tool steel wheels.

Once a double start thread was made, the use of gearing would allow it to be used on a thread-cutting lathe to make a single start thread, I think. Yes, it would. As well as making the thread cut depth more uniform, and changing the diameter, pitch and depth of the screw.

There is a third possibility, but i don’t recommend it. Draw wire through a triangular dye to make triangular wire. Then glue the triangular wire around a rod to make a screw thread. The only real advantage of this is that a nut could be made the same way. Not suitable for a fastening, but possible for a template screw for a thread-cutting lathe.

What about a thread-rolling flat dye? Simply cut by lathe without need for a screw thread?

Ian said:

Anyway, this is smashing viewing. The thread-rolling flat dye in action.

Bolt Manufacture

A hand-operated tool could make a single start thread using a couple of rollers, too. Hot forge. That’s how I’d do it, if I wanted to kick-start the threaded bolt technology from scratch. I’d make the rollers on a rivetted lathe.

—-

The flat dye rolling method could also be made without a thread to start with. Even by hand without a lathe.

Start by making something that looks like a saw, but has even triangular teeth. May as well do this with a file.

Strengthen by heat treatment and clamping between thick plates.

Set a rectangular plate at a small angle, and drag (by hand will do) the saw sideways across it, cutting slots. By hand, slowly deepening the grooves.

Repeat with a second plate. Harden by heat treatment.

Then make the thread on the bolt exactly as in the video. But again by hand and hot forging.

Take one bolt made this way and cut three or four wide grooves down its length. Harden by heat treatment. You now have a tap-n-dye tool for making nuts.

A little cutting paste on a bolt will increase the clearance between bold and nut.

Done, and not a lathe in sight.

Date: 5/03/2019 05:07:40

From: Michael V

ID: 1355487

Subject: re: Bolt, nut, spanner, screw, screwdriver?

mollwollfumble said:

mollwollfumble said:

Look. I can see two possibilities. One is that some craftsman with a triangular file cut a spiral groove in some metal, such as brass, by hand. That’s still not good enough on its own unless someone sand-cast the first metal nut around the screw and finished the casting by hand using, for instance, a polishing compound between screw and nut.

The other possibility is a tool that I’ve never seen but I think could be made. A hand-operated tool to make a double start thread could be made without the need for a screw thread to start it. Using a pair of wheel and axles set opposite one another mounted in a sand cast body. Each wheel is of a hardened material such as tool steel, rhombus in cross section with a pointed rim. Like this.

The wheels and axles could be made by hand or, easier and better, made in a lathe which was of rivetted construction.

By using axles that are not parallel to each other, the wheels could press double-start threads into a soft material such as brass or (possibly) annealed steel. The sand cast body would include handles, and look something like this, but containing the tool steel wheels.

Once a double start thread was made, the use of gearing would allow it to be used on a thread-cutting lathe to make a single start thread, I think. Yes, it would. As well as making the thread cut depth more uniform, and changing the diameter, pitch and depth of the screw.

There is a third possibility, but i don’t recommend it. Draw wire through a triangular dye to make triangular wire. Then glue the triangular wire around a rod to make a screw thread. The only real advantage of this is that a nut could be made the same way. Not suitable for a fastening, but possible for a template screw for a thread-cutting lathe.

What about a thread-rolling flat dye? Simply cut by lathe without need for a screw thread?

Ian said:

Anyway, this is smashing viewing. The thread-rolling flat dye in action.

Bolt Manufacture

A hand-operated tool could make a single start thread using a couple of rollers, too. Hot forge. That’s how I’d do it, if I wanted to kick-start the threaded bolt technology from scratch. I’d make the rollers on a rivetted lathe.

—-

The flat dye rolling method could also be made without a thread to start with. Even by hand without a lathe.

Start by making something that looks like a saw, but has even triangular teeth. May as well do this with a file.

Strengthen by heat treatment and clamping between thick plates.

Set a rectangular plate at a small angle, and drag (by hand will do) the saw sideways across it, cutting slots. By hand, slowly deepening the grooves.

Repeat with a second plate. Harden by heat treatment.

Then make the thread on the bolt exactly as in the video. But again by hand and hot forging.

Take one bolt made this way and cut three or four wide grooves down its length. Harden by heat treatment. You now have a tap-n-dye tool for making nuts.

A little cutting paste on a bolt will increase the clearance between bold and nut.

Done, and not a lathe in sight.

>>>tap-n-dye

Poor nomenclature that has been used throughout this thread. There is no such thing as a tap-n-dye tool (nor tap-n-die tool). Taps and dies are often purchased in sets – tap and die sets.

- A die is a (female) tool that cuts an external (male) thread.

- A tap is a (male) tool that cuts an internal (female) thread.

I have made taps to repair damaged threads by hand-shaping a bolt.

Likewise, I have made dies to repair damaged threads by hand- shaping a nut.

Date: 5/03/2019 12:28:00

From: Ian

ID: 1355540

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Poor nomenclature that has been used throughout this thread.

—

We can’t have that. It’s my not fault.. well only a bit :)

This the sort of small Tap and die set to which I referred.

My reference to a large tap and die set should have read just “die set” (only used on gal pipe, with female joiners, before poly pipe took over).

Molly misquotes me referring to a “dye”.

Date: 5/03/2019 13:10:10

From: Michael V

ID: 1355552

Subject: re: Bolt, nut, spanner, screw, screwdriver?

Ian said:

Poor nomenclature that has been used throughout this thread.

—

We can’t have that. It’s my not fault.. well only a bit :)

This the sort of small Tap and die set to which I referred.

My reference to a large tap and die set should have read just “die set” (only used on gal pipe, with female joiners, before poly pipe took over).

Molly misquotes me referring to a “dye”.

Yeah, I noticed. I have a cheap, useless junk-metal metric tap and die set. Really only good for cleaning threads. I however have both tap and dies made by P&N (Patience & Nicholson) and Sutton, both good quality brands, bought for individual jobs. I also have some large square pipe dies, that match no threads whatsoever. And a big hand-forged-steel die-handle (not for those dies).

I also have a blacksmith-made adjustable square-jaw wrench. Its square thread must have been forged before the handle was twisted and the jaws were forged. Unfortunately the adjuster-nut has rusted to the thread. I’d love to fix that. Perhaps one day I’ll try electrolytic rust removal.

Date: 7/03/2019 17:31:49

From: roughbarked

ID: 1356629

Subject: re: Bolt, nut, spanner, screw, screwdriver?

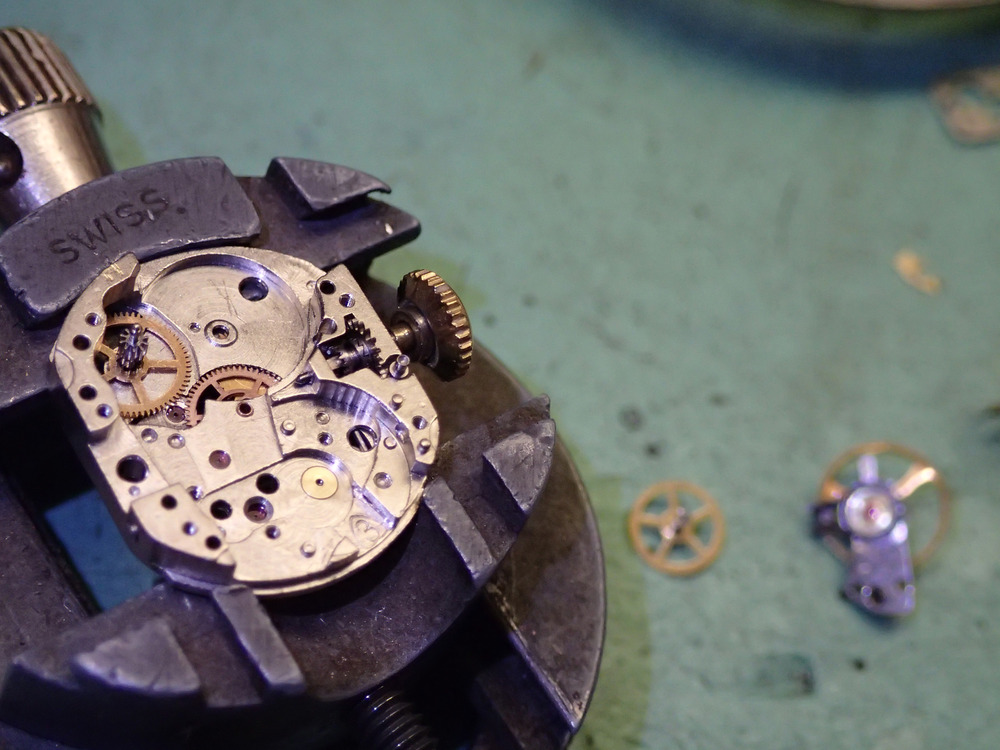

a Russian small ladies watch I had to find a screw for.

Date: 7/03/2019 17:34:20

From: roughbarked

ID: 1356630

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

a Russian small ladies watch I had to find a screw for.

Can you guess which screw I provided?

Date: 7/03/2019 17:39:28

From: The Rev Dodgson

ID: 1356631

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

a Russian small ladies watch I had to find a screw for.

What do Russian watches for large ladies look like?

Date: 7/03/2019 17:47:23

From: roughbarked

ID: 1356632

Subject: re: Bolt, nut, spanner, screw, screwdriver?

The Rev Dodgson said:

roughbarked said:

a Russian small ladies watch I had to find a screw for.

What do Russian watches for large ladies look like?

:)

Gent’s watches.

Date: 7/03/2019 17:49:09

From: party_pants

ID: 1356633

Subject: re: Bolt, nut, spanner, screw, screwdriver?

The Rev Dodgson said:

roughbarked said:

a Russian small ladies watch I had to find a screw for.

What do Russian watches for large ladies look like?

In Soviet Union, large Russian ladies wear you.

Date: 7/03/2019 17:50:10

From: roughbarked

ID: 1356635

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

roughbarked said:

a Russian small ladies watch I had to find a screw for.

Can you guess which screw I provided?

In case you are guessing, there are actually two.

Date: 7/03/2019 18:04:09

From: roughbarked

ID: 1356641

Subject: re: Bolt, nut, spanner, screw, screwdriver?

roughbarked said:

roughbarked said:

roughbarked said:

a Russian small ladies watch I had to find a screw for.

Can you guess which screw I provided?

In case you are guessing, there are actually two.

In my case, I was full of wonder at how well the Russians could copy a Swiss design and translate it into something that almost looks completely different but yet the same. I was inclined to think that maybe they’d bought one of the ETA movement designs thta ETA had decided not to use. I actually replaced the missing screws with Swiss screws from ETA movements.

In putting it back together.