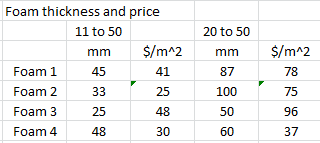

Material science, a tale of 4 foams.

Just measured stress-strain curves for 4 foams.

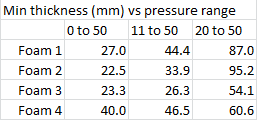

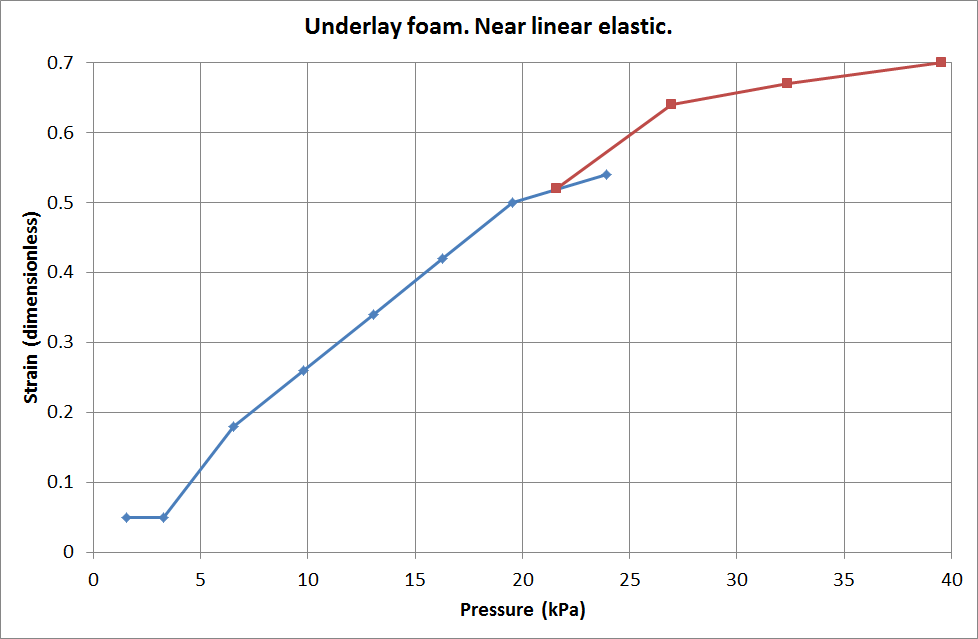

Foam 1. Carpet underlay. Very close to linear elastic, deviates from linear only because foam can’t be compressed 100% because there’s some solid material there to stop that happening. The two curves are two different bearing areas.

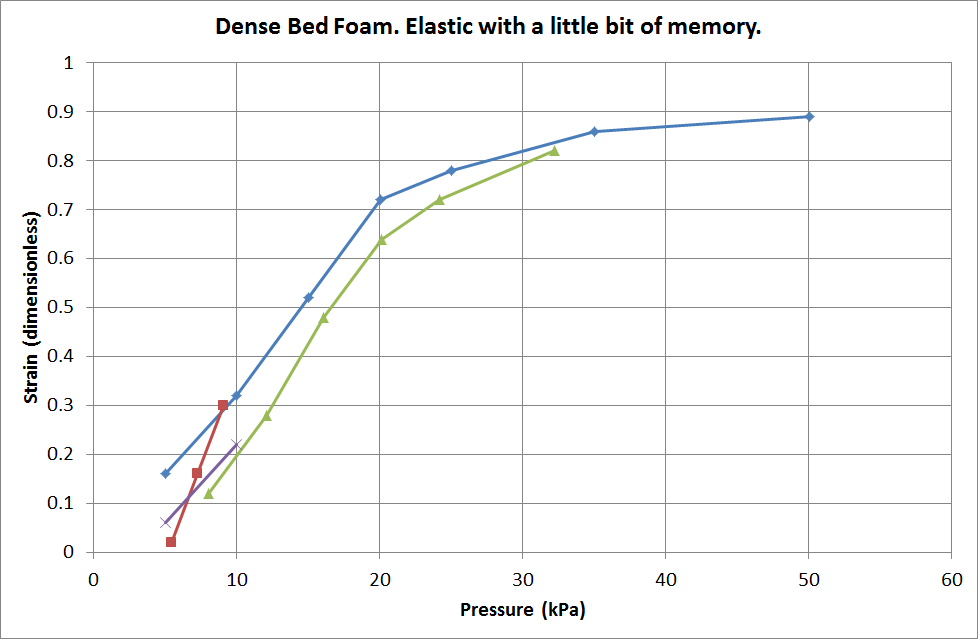

Foam 2. Dense bedding foam. Not far from linear elastic but a little memory effect. Memory effect means higher pressure at small deflection at shorter times. Three curves are different bearing areas, the fourth curve failed to wait long enough for memory effect to kick in.

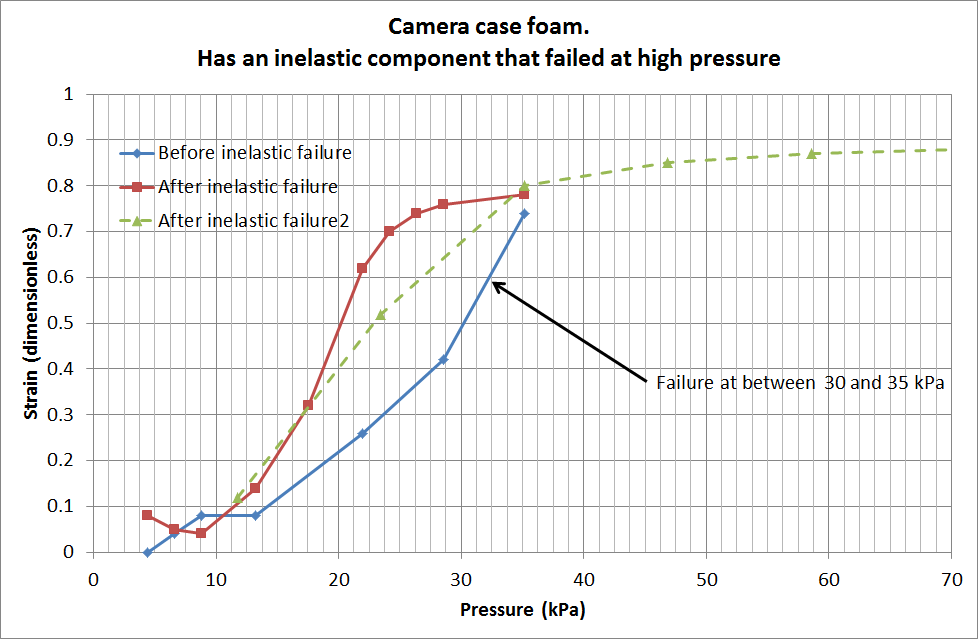

Foam 3. Camera case foam. The foam has an elastic and inelastic component, the inelastic component failed somewhere between 30 and 35 kPa. Thereafter, a relatively low pressure caused a high deflection.

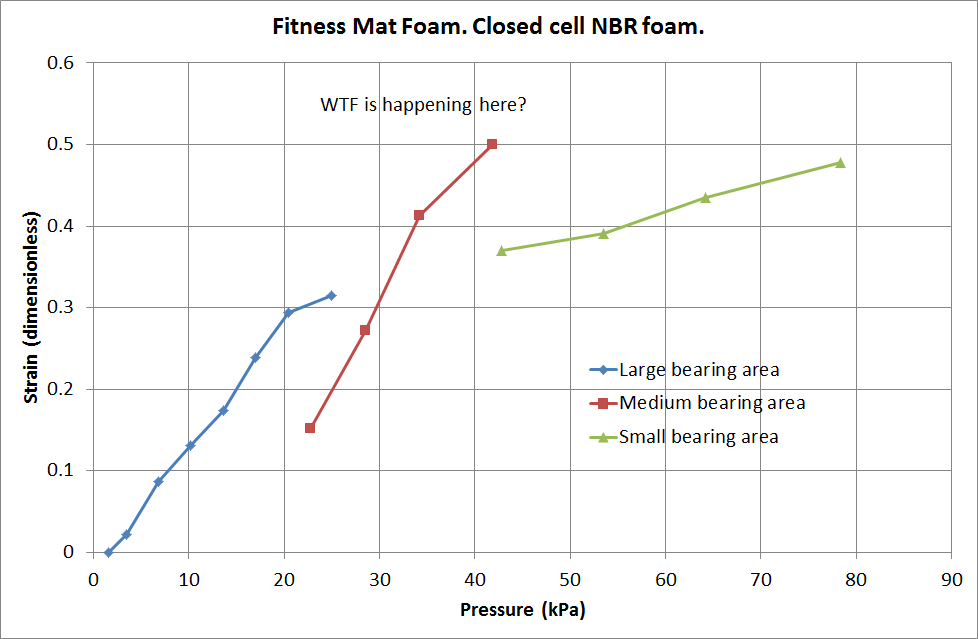

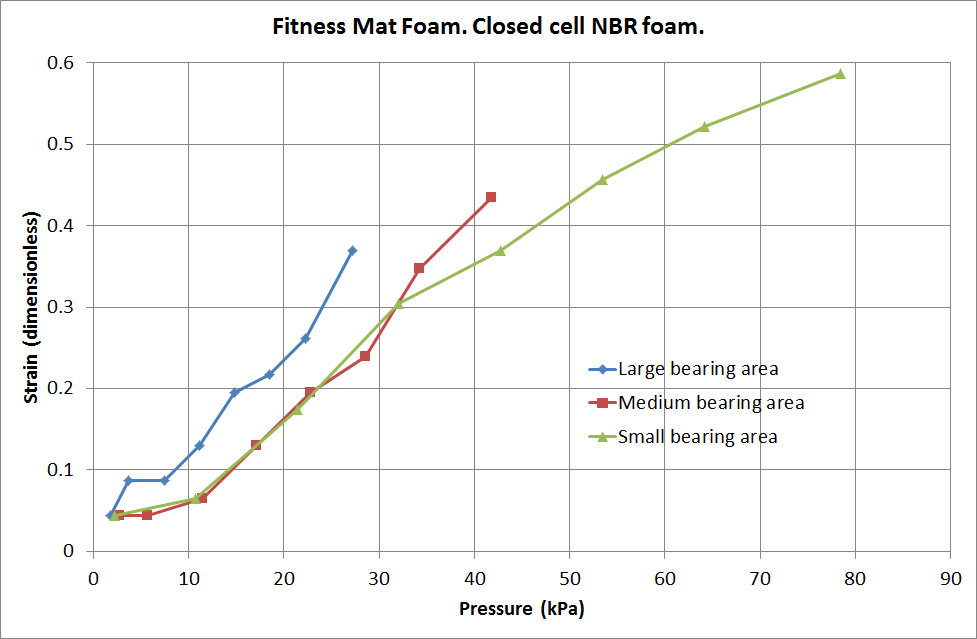

Foam 4. That the hell is happening here? Foam for an exercise mat. Type of foam “Closed cell NBR”. Changing the bearing area has a huge effect on the deflection at given load. So much so that a load of 10 kg causes the same deflection when applied to two different bearing areas that differ by nearly a factor of 2 in area. No memory effect and no failure of an inelastic component.