The following comes from four sources. One is a translation from the Russian wikipedia.

A new state of matter? Not quite, but intermediate between glassy solids and crystalline solids in much the same way that a liquid crystal is intermediate between a liquid and a crystalline solid. It contains nanoscale crystals in a glassy matrix.

The original problem was getting a low coefficient of thermal expansion for large telescope mirrors.

Sitall is a crystalline glass-ceramic with ultra-low coefficient of thermal expansion (CTE). It was originally manufactured in the former Soviet Union and was used in the making of primary mirrors for the Russian Maksutov telescopes. The Southern African Large Telescope (SALT) selected Sitall for the manufacture of its 91 primary mirror segments. The choice arose out of increased scientific collaboration between Russia and South Africa. Sitall was also used for the primary and secondary mirrors of the VLT Survey Telescope.

Sitalls are glass-crystalline materials obtained by bulk crystallization of glasses and consisting of one or more crystalline phases uniformly distributed in the glassy phase. Developed by the Soviet physicochemist I.I. Kitaygorodsky . Materials similar to ceramic materials are called pyrocerams, devitrocerams, and glass ceramics abroad.

According to their purpose, they are divided into technical, construction, jewellery. According to the main property and purpose, they are divided into high-strength, radiolucent chemically resistant, transparent heat-resistant, wear-resistant and chemically resistant, photo-metals, mica-glass, bio-metal, glass-ceramic, glass-metal enamel, glass-ceramic with special electrical properties.

For chemical composition see https://sci-hub.tw/10.1007/BF00678634 . “In the present work we investigated composite sitall ceramic materials (USSR Inventor’s Certificate 1264531) composed of Al2O3 and sitall-forming glass of the BaO – CaO – Al203 – B203 -TiO2 – SiO2 system (composition 3V). In crystallization, this glass forms strong and heat-resistant crystalline phases, namely, β-celsian, anorthite and rutile. The amount of glass was varied from 10 to 90% by weight as the Al203 content was varied from 90 to 10%.” Higher alumina content resulted in better physical properties. Sitall is “recommended for the production of guide stops for tape-winding mechanisms, engine parts in the automobile industry, pump gaskets, and structural parts operating in conditions of elevated friction.”

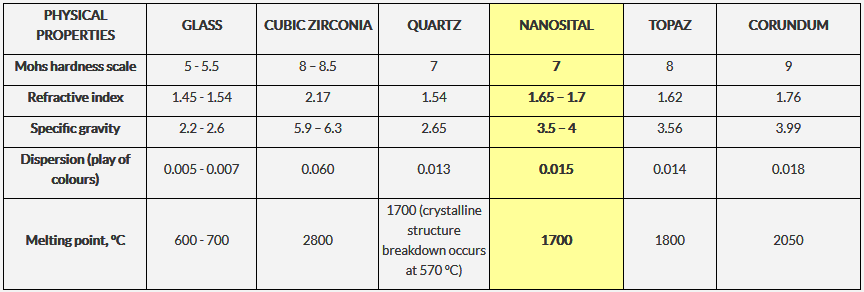

As gemstones, marketed as Nanosital, they have the advantage of easy availability in a very large range of colours. One forum mentions that they can have a heap of rare earth elements added. They have the following properties.