Battery made of aluminum, sulfur and salt proves fast, safe and low-cost.

Engineers at MIT have developed a new battery design using common materials – aluminum, sulfur and salt. Not only is the battery low-cost, but it’s resistant to fire and failures, and can be charged very fast, which could make it useful for powering a home or charging electric vehicles.

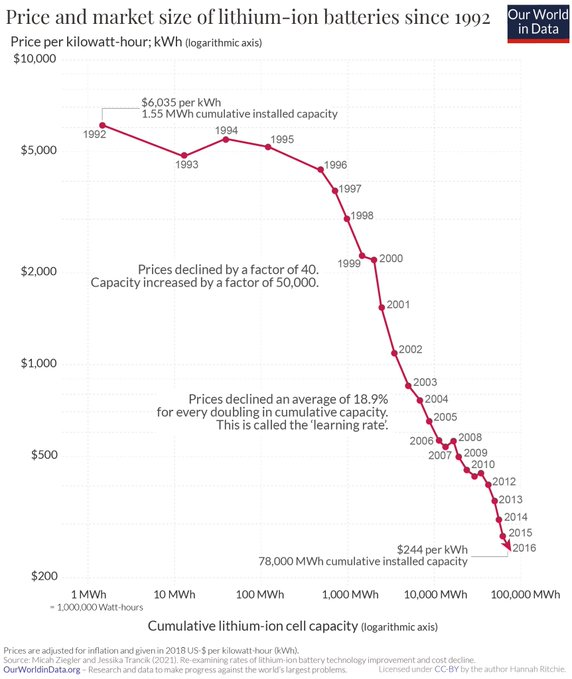

Lithium-ion batteries have dominated the field for the last few decades, thanks to their reliability and high energy density. However, lithium is becoming scarcer and more expensive, and the cells can be hazardous, exploding or bursting into flames if damaged or improperly used. Cheaper, safer alternatives are needed, especially as the world transitions towards renewable energy and electric vehicles.

So the MIT team set out to design a new type of battery out of readily available, inexpensive materials. After a search and some trial and error, they settled on aluminum for one electrode and sulfur for the other, topped off with an electrolyte of molten chloro-aluminate salt. Not only are all of these ingredients cheap and common, but they’re not flammable, so there’s no risk of fire or explosion.

In tests, the team demonstrated that the new battery cells can withstand hundreds of charge cycles, and charge very quickly – in some experiments, less than a minute. The cells would cost just one sixth of the price of a similar-sized lithium-ion cell.

newatlas.com/energy/aluminum-sulfur-salt-battery-fast-safe-low-cost/

No mention of energy density though. But it’s implied as the article mentions they’d be good for home batteries, etc.